At Accu-Glass, our goal is to provide you the best glass tubing solutions by using our proprietary glass melting processes, customized glass manufacturing equipment, and advanced measurement systems. We will work with you through your design and development process to build the right components that can be integrated into your devices.

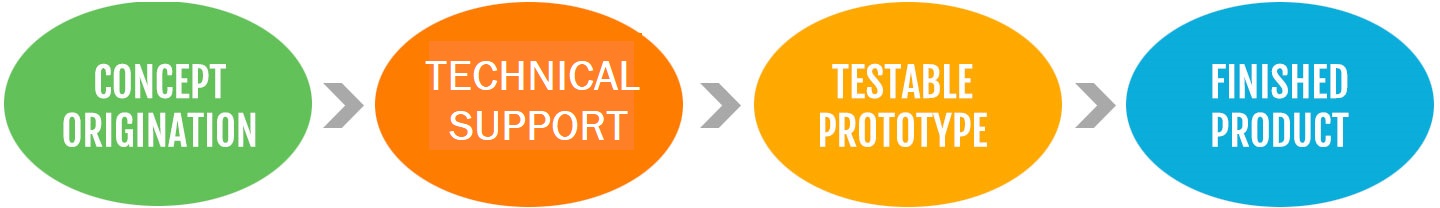

Concept Origination

We collaborate with you to translated your design concept into a precision glass tubing solution. Glass is a material that offers precision, reliability, and flexibility in manufacturing. Markets served include medical device, point-of-care, clinical, laboratory, and fiber optics.

Design Consultation

The Accu-Glass sales and engineering team is ready to provide technical assistance on your glass application. Our engineers will collaborate with you on new products or enhance an existing product. Let us show you the true benefits and performance results you can achieve with glass.

Testable Prototype

As a premier precision glass tubing manufacturer, flexibility is a hallmark of our business. Custom-designed systems are employed to provide the precise dimensional measurements for your requirements. Accu-Glass’ proprietary glass forming process as well as re-draw allows the fastest response in the industry.

Finished Product

From concept to finished product packaging, Accu-Glass is a leader in innovation. After successful prototype evaluation, AG implements the design solution into the manufacturing process. Commitment to quality engineering and service is our strength.

Find out how Accu-Glass can solve your precision glass tubing problems.